Check Yourself Before You Wreck Yourself: How Much Risk Reduction is Enough? (Part Four)

- February 3, 2021

- Best Practices

- Automation

Where do you start when you want to achieve safety in a real-world manufacturing environment? There’s so much information out there about how to conduct risk assessments because they’re the first step toward reducing hazards. If you take time to conduct a risk assessment thoroughly, it serves as a solid foundation to preserve productivity, keep everyone safe, and diminish the chance of accidents.

The goal with any risk assessment is to reduce risk to an acceptable level, whether it’s through designing potential hazards out of a machine or using proper personal protective equipment.

In simplified terms, a risk assessment consists of two parts. First, you assess the machine as if there were no safeguards in place at all: no fencing, no gates, no light curtains, etc. From that assessment, you assign a risk rating: negligible, low, medium, high, or very high.

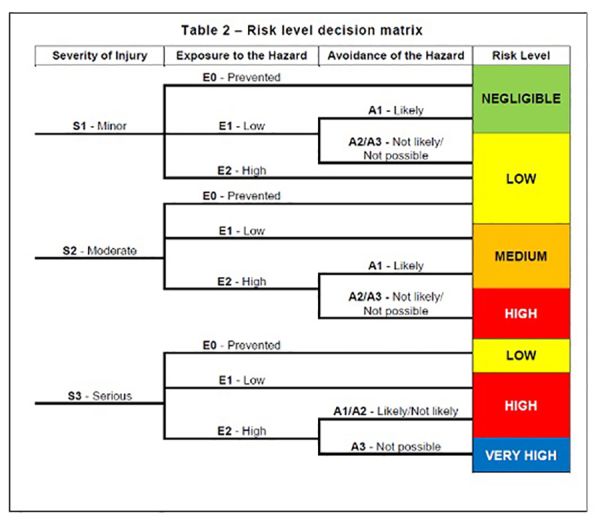

Remember this chart below from our first blog in this series on machine safety steps? The combination of injury severity, exposure, and avoidance guides you to the appropriate risk level.

After your tasks/hazard pairs have been identified and rated, you’re ready for the second half of your risk assessment: identifying ways to reduce risk to an acceptable level.

What “acceptable level” means is up to you and your company because the standards do not tell you what “acceptable risk” is. I have witnessed in many applications typically “negligible” or “low” is the goal.

ANSI/RIA TR R15.306 describes a six-step approach to risk reduction, starting with the most-preferred measures to reduce risk. You should consider every risk reduction measure for each task/hazard pair on your risk assessment.

- Elimination: Can you design the hazard out of the machine or automate the task to keep the operator out of the hazard area?

- Substitution: Can you reduce speed, torque, pressure, etc. to improve safety?

- Safeguarding: What safeguards can you add to the machine to reduce risk? (Fixed guards, movable guards, electronic protection devices like safety mats or light curtains, etc.)

- Warnings: What mechanisms can you put in place to make sure employees are aware of the machine and its potential risks? (Lights, beacons, alarms, beepers, etc.)

- Administrative Controls: What processes and procedures can be implemented to support risk reduction? (Confined space entry, training, inspections, etc.)

- Personal Protective Equipment: What apparel needs to be worn to ensure safety while operating the machine? (Safety glasses, shield, gloves, hard hat, etc.)

View more about this hierarchy of risk-reduction measures here »

Note that No. 3 on the list above is Safeguarding. If you can’t eliminate or substitute to reduce the risk to an acceptable level, then safeguards should be considered. If your choice of safeguard is a movable guard, gate, or electronic safety device, then you need to know the Required Performance Level (PLr). This is absolutely necessary in order to design your safety circuit. We first talked about PLrs in the first blog post of this series: Part One: Balancing Ideal-World Machine Safety with Real Life.

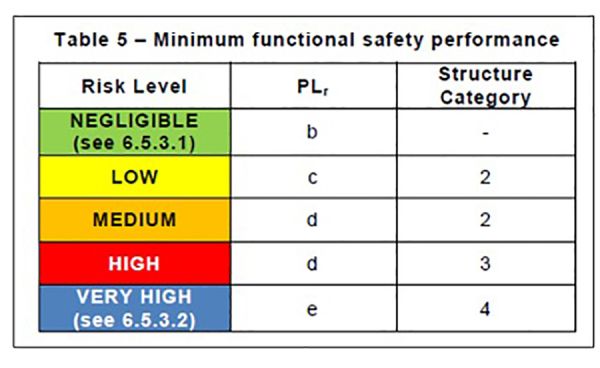

Once you know your risk level, you can use the table below to determine your PLr.

By taking steps to reduce your risk to an acceptable level and knowing your required Performance Level when you use an electronic safety device, you can significantly reduce risk, preserve uptime, maintain compliance, and keep workers safe.

Want to learn more about machine safety and safety standards? Start with these three blogs in our safety series:

- Part One: Balancing Ideal-World Machine Safety with Real Life

- Part Two: Where to Start with Machine Safety Standards

- Part Three: Battle Royale: Performance Level Vs. Safety Level

As you move through this process, don’t hesitate to ask us questions. We have many TUV-certified machine safety engineers and technicians who are happy to help.

Stay tuned for more blogs in our safety series! Next up: We’ll discuss where to begin when assessing the safety of an existing machine.

ARTICLE BY:

RANDY TURNER

EMPLOYEE-OWNER, SOLUTION CONSULTANT

For more information about Van Meter’s industrial controls solutions, please call 1-800-247-1410.