Balancing Ideal-World Machine Safety with Real Life: 5 Steps to Follow (Part One)

- August 13, 2020

- Best Practices

- Automation

Machine safety is harder than it used to be. Gone are the days of simply turning machines or components off with a master control relay and calling it a day.

Then, in the late 1990s, control reliability became part of ANSI safety standards. This meant that machinery safety circuits needed to be redundant and monitored (self-checking) so that, if one component failed, the other would still be able to stop the hazard.

Fast forward to today: Now, safety is all about statistics. How many times can you use the safety circuit? What’s the life expectancy before it fails – in a dangerous, undetectable way?

In addition to safety being more complicated today, safety is also more important than ever. Risks can result in steep fines, lost productivity, and injuries (or worse). By pinpointing each machine’s potential safety risks and correcting those issues as much as possible, the chance of accidents and downtime can be greatly reduced.

We all know that the “real world” is much different than what ANSI and ISO safety standards propose. The standards expect you to follow these steps of machine safety:

- Conduct a team-based risk assessment to identify hazards

- Write a functional safety specification

- Design and verify safety functions

- Conduct validation testing to evaluate design and technical measures

- Create and carry out a maintenance plan

Let’s say you’ve been instructed to make a piece of equipment safer: installing a light curtain, preventing a gate from opening while the machine is running. You’ve got these five ideal-world steps to follow listed above, but not enough time or resources available. Even though the standards call for a team-based risk assessment, it’s highly likely that only one person is available to do the work. So how should you begin if you’re living in the real world vs. the “ideal world”?

Step 1: Conduct a Risk Assessment

We recommend starting with a risk assessment you can conduct on your own, by doing a quick and easy self-assessment of the hazard. The goal is to reduce risk to an acceptable level. The steps below are what the safety standards instruct you to do:

- Designing potential hazards out of the machine

- Applying fixed or movable guards when possible

- Deploying another level of safeguarding utilizing electronic safety components (light curtains, gate switches, etc.) when possible

- Using awareness controls (lights, beacons, strobes, beepers, horns, computer warnings, etc.) when possible

- Implementing administrative controls (training, documented procedures, inspections, etc.)

- Using proper PPE (eye and face protection, etc.)

This risk assessment can lead you to the machine’s required performance level (PLr). ANSI/RIA TR R15.306 is a good guideline to use for your risk assessment. Although the methodology was created by the Robotics Industries Association, it can be used for any type of industrial machine.

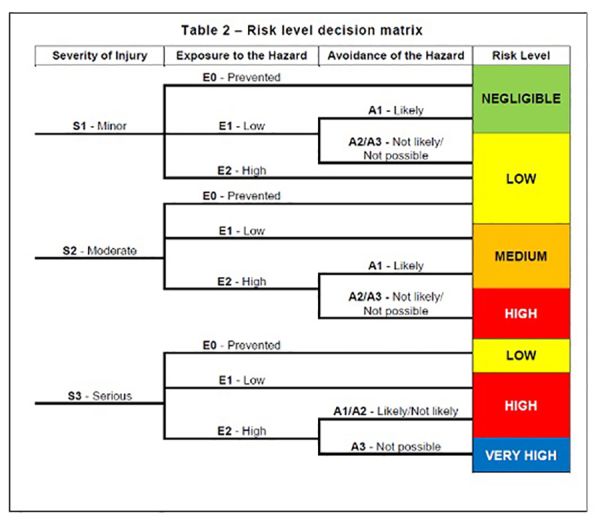

To conduct a risk assessment on your own, simply walk yourself through RIA’s Risk-Level Decision Matrix (pictured below) using the definitions and your familiarity with the machine:

- How severe will an injury be if someone is exposed to this hazard (bruises, broken bones, chronic illness, etc.)?

- How often is someone exposed to this hazard (once a day, multiple times a day, no exposure if certain design measures are taken, in short increments, over long periods of time, etc.)?

- How easy will it be for someone to avoid the hazard (adequate warning time to move out of the way, no safeguarding, etc.)?

With answers to these questions, you can then assign a risk level ranging from “negligible” to “very high.” Definitions for severity, exposure, and avoidance are available in the RIA TR R15.306 standard.

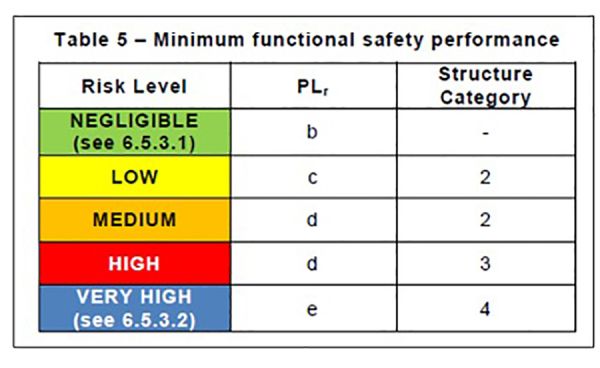

Step 2: Identify the Required Performance Level

Once you know your risk level, you can pinpoint your PLr (required performance level) for each safety function using the table below, which is also found in ANSI/RIA TR R15.306, to ensure compliance.

Step 3: Write a Sequence of Operation

After you’ve identified the PLr for the machine, our next recommendation is to create a sequence of operation: Write a short paragraph explaining what happens when the safety circuit is activated.

In some situations, these will be simple, one-sentence statements: “When I open the gate, everything on the machine stops”. In other situations, the paragraphs will be more complex because the machine is zoned: “Portions of the machine will maintain power while other components turn off”.

Take the sequence of operation and PLr to the person who requested the safety changes (your HSE leader, for example) and get a second opinion: Make sure they agree with your plan.

Step 4: Select Safety Components

With your PLr identified and your sequence of operation documented, you are now ready to design your safety circuit and select the proper safety components. Knowing where to mount safety devices is a critical part of this step. ANSI B11.19-2019 outlines simple, easy-to-follow distance calculations and height requirements to help with this.

Step 5: Verify Performance

The last step we recommend is to verify that the performance level (PL) of your safety circuit meets the PLr. The easiest way to accomplish this is to use free SISTEMA software, which will tell you whether the PL of your circuit design and chosen hardware meet the required performance levels you pinpointed in your risk assessment. This software does the statistical math for you.

Where to Turn to Learn More About Machine Safety

Although properly implementing safety involves much more than the steps outlined above, this is a good starting point to familiarize yourself with current methods.

In the real world – which is full of time constraints and limited resources – following the process we outlined above is the simplest way to implement a safety circuit on a machine. You will be much more successful in meeting the “intent” of current safety standards if you follow these steps.

Want to learn more about safety standards, risk assessments, circuit design, distance calculations, and SISTEMA software? Don’t hesitate to ask us questions. We have many TUV-certified machine safety engineers and technicians who are happy to help. And stay tuned for more blogs soon to come in our safety series!

RANDY TURNER

EMPLOYEE-OWNER, SOLUTION CONSULTANT - SAFETY

For more information about Van Meter’s industrial controls solutions, please call 1-800-247-1410.