Discover your (smart manufacturing) potential

The industrial manufacturing environment is changing fast with new, emergent technologies. Learning how to effectively use these technologies can transform how you do business today, optimize your business for the future and manage costs to keep up with the change.

BLOOMINGTON, MN

Hyatt Regency Bloomington-Minneapolis

3200 E 81st St, Bloomington, MN 55425

THURSDAY, APRIL 24, 2025

CORALVILLE, IA

Hyatt Regency Coralville

300 E 9th St, Coralville, IA 52241

TUESDAY, MAY 13, 2025

Gain industry insights through a variety of educational sessions ranging from concepts presented by

industry thought-leaders to hands-on workshops and technical sessions.

LEARN ABOUT THE AVAILABLE SESSIONS

BE SURE TO REGISTER FOR YOUR SESSIONS PRIOR TO THE EVENT

BEYOND SPREADSHEETS & DATABASES: UNLOCK OPERATIONAL POTENTIAL THROUGH DIGITAL PROCESSES

Manual processes make production orders more complex, cumbersome and error-prone. How do you identify opportunities for digitization? We’ll walk through the life of a production order to identify the manual processes that can create challenges and highlight the digitization solutions that can optimize your production scheduling, traceability, quality and performance.

BUILD YOUR CYBERSECURITY APPROACH WITH SENSOR-TO-CLOUD SOLUTIONS

Like the walls of your home should be sturdy enough to protect you from the elements, a good cybersecurity defense should have layers of defense against external threats. In this session, we will give you a cybersecurity framework you can apply to everything from machinelevel security to cloud connectivity, so you can keep your data secure and avoid costly downtime from a cybersecurity incident.

ADDRESS YOUR BIGGEST BUSINESS CHALLENGES WITH AUTONOMOUS MOBILE ROBOTS (AMR)

Struggling with production goals, workforce retention, skills gaps and floor space? Learn how autonomous mobile robots can address each of those challenges to see whether you should invest in AMRs and what you should consider when deploying them.

LEVERAGE ON-MACHINE SOLUTIONS TO OPTIMIZE YOUR MACHINE DESIGNS

Optimize panel space while reducing engineering, labor and changeover time – it’s all possible with smarter, more flexible machines. Learn how to be more efficient with independent cart technology, robotics, onmachine and digital twin solutions.

ALL IN ON AI: USE CASES YOU CAN APPLY RIGHT NOW

Do you know how to make AI work for you? Learn specific AI applications to address your manufacturing challenges through smart manufacturing solutions like Model Predictive Control, GuardianAI, Logix AI, Vision AI and smart devices like the PowerFlex 755TS VFD.

MODERNIZED MACHINE SAFETY FOR MAXIMIZED PRODUCTION

You shouldn’t have to choose between safety and production. Learn about machine safety technology and techniques that get your production floor to zero accidents (or near misses) while diagnosing production stops more quickly, simplifying installation and improving workforce and production efficiency.

OPTIMIZE YOUR CAPITAL EXPENDITURES: WHAT TO INVEST IN BEFORE INVESTING IN YOUR BUSINESS

Before you invest in a capital project for your business, have you invested in a strategy? This session will explore concepts to optimize your project through defining scope of work, functional requirements, selecting the right partners and managing timelines. You will hear reallife examples of how these strategies were put into place to achieve a successful project, on time and on budget.

EXPLORE THE FASTER ROI OF COLLABORATIVE ROBOTS

Stop, collaborate and listen to the ways collaborative robots lead to quicker ROI by addressing your workforce, productivity and safety challenges.

DATA TO DECISIONS: CREATE CONTEXT WITH MANUFACTURING DATA

Collecting all the data you can without a clear data strategy is like drinking through a fire hose. How can you funnel that data into actionable insights you can use to make faster, smarter decisions? From sensors to software to smarter solutions, discover how you can develop a data-driven culture with smarter equipment and a clear data strategy.

BUILD SMARTER, MORE FLEXIBLE MACHINES

Explore how taking a decentralized, modular approach to machine building with on-machine solutions can reduce wiring, machine footprint and time-to-market for more flexibility on your plant floor.

REACH PEAK RELIABILITY WITH PREDICTIVE MAINTENANCE TOOLS & TECHNOLOGY

Learn how to develop a reliability strategy that integrates predictive maintenance tools and technologies with equipment lifecycle management, technical support and training. Plus, you’ll see how internal collaboration and change management drive downtime reduction, Mean Time to Repair (MTTR), Mean Time Between Failures (MTBF) and labor optimization.

Experience Technical Labs

- FactoryTalk Optix

- Remote Access

- ThinManager Software

- FactoryTalk View

For more information about these labs, see the “Visualization for Visionaries” sessions on the agenda.

MEET OUR KEYNOTE SPEAKERS

Over the lunch hour, join us for a keynote by our partners at Rockwell Automation.

TODD GILLIAM

Minnesota Keynote

Todd Gilliam is Rockwell Automation’s North American Industry Leader for Consumer Packaged Goods. He is responsible for accelerating growth in Rockwell’s largest industry vertical and guiding Digital Transformation and Connected Enterprise journeys through the latest manufacturing business trends and challenges.

COLIN SPEAKMAN

Iowa Keynote

Colin Speakmann has been helping leaders transform their organization for more than 20 years. He has advised R&D leaders investing in capabilities, innovation platforms or technologies, operations leaders driving efficiency through automation investments and executives turning organizational vision into tangible actions.

PRODUCT SHOWCASE

- GuardianAI – Optimize maintenance activities and reduce unplanned downtime with advanced notice of upcoming asset failures provided by FactoryTalk® Analytics™ GuardianAI™. When maintenance engineers understand the health of the assets on the plant floor, they can plan their tasks efficiently. FactoryTalk Analytics GuardianAI provides continuous condition-based monitoring, alerting the maintenance team when an asset begins to show signs of degradation and providing insights into the most probable cause of failure. With this information, they can plan when to perform the required repair and confirm they have the necessary resources and parts on hand. Repair times are reduced and costly unexpected downtime is avoided. Aligns with “Let’s Get it Started: Drives Installation Best Practices” session.

- PowerFlex 755TS – Adaptive Control - Need around-the-clock dependability? Let PowerFlex® 755TS variable frequency drives do the heavy lifting. You’ll increase productivity and uptime plus, reduce energy and maintenance costs. Featuring patented TotalFORCE® smart technology, these six-pulse variable frequency drives deliver flexible, high-performance motor control, real-time operational intelligence and eased application commissioning and optimization. Designed for countless motor control applications and industries – from standard to the most demanding industrial control challenges – these VFDs help deliver the productivity and throughput you need. Aligns with “Let’s Get it Started: Drives Installation Best Practices” session.

- ArmorKinetix – A new era has arrived in On-Machine™ motion control. We are raising the bar on what is possible in your next machine design with ArmorKinetix® Distributed Servo Drives. This drive platform offers the high-performance of the Kinetix® 5700 Servo Drive in a compact, On‑Machine form factor that enables your production machines to become more efficient, flexible and cost-effective than ever before. Aligns with “Leverage On-Machine Solutions to Optimize Your Machine Designs” session.

- InCabinet Ethernet/IP – Rockwell Automation’s EtherNet/IP™ networks provide plant-wide network systems using open, industry-standard networking technologies. It enables real-time control and information in discrete, continuous process, batch, safety, drive, motion, and high availability applications. The EtherNet/IP network connects devices such as motor starters and sensors to controllers and HMI devices and on into the enterprise. It supports non-industrial and industrial communications on a common network infrastructure. Aligns with “Modernized Machine Safety for Maximized Production” session.

- “Viz Tree” – Complete range of Industrial PC's, Human/Machine interface hardware and software, remote access capabilities, secure Industrial IoT gateway solution. Aligns with Visualization for Visionaries sessions.

- Guardlink – Allen‑Bradley Guardmaster® smart safety devices that feature GuardLink technology deliver information, advanced functionality, and flexibility. This technology helps enhance safety and increase machine- and plant-wide efficiency. Aligns with “Modernized Machine Safety for Maximized Production” session.

- Industrial robotics demonstrations:

- Collaborative Robot: Often referred to as cobots, these robots are cost efficient and within reach for any organization. Known to be lightweight and flexible, cobots can work safely alongside people to improve quality, consistency and safety. The ease of programing allows them to be reprogrammed and redeployed to different tasks as often as needed. Aligns with “Build Smarter, More Flexible Machines” session.

- Robotic Palletizer, BeRobox – Make a substantial impact on your palletizing operations by overcoming labor shortages, enhancing worker safety and increasing productivity in today’s market. Within five minutes, you can integrate and deploy a beRobox palletizing work cell without any workflow disruptions. beRobox units are powered by STACKiT, beRobox’s proprietary software, making operation of the work cell straightforward, ensuring maximum uptime and efficiency. A single operator can simplify and amplify the entire palletizing process with beRobox's automated palletizing solutions. Aligns with “Explore the Faster ROI of Collaborative Robots” session.

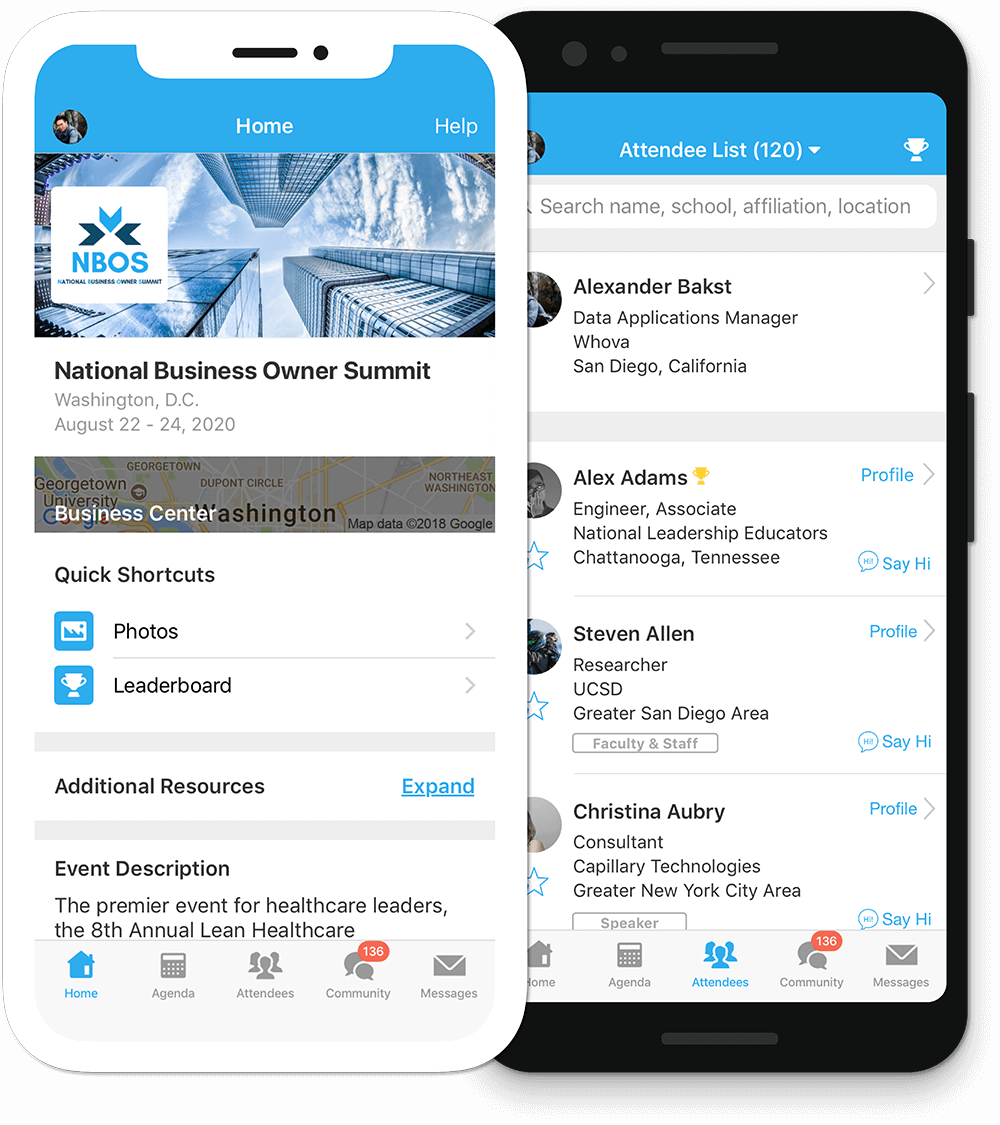

Event App

Download the Whova event app to get the most out of your Smart Solutions Summit experience:

BLOOMINGTON, MN

Download appCORALVILLE, IA

Download appEverything You Need to Succeed

Questions? Reach out to Jessica Joyce at [email protected].