Keeping Current: How FactoryTalk Hub Will Transform the Way You Work

- December 22, 2022

- Video

- Automation

You may have used the cloud to store and access personal photos, music and documents, but do you know how the cloud can improve the quality and scale of your manufacturing production? If you are cloudy on the details, watch the video below or read on to clear up the ways FactoryTalk Hub, Rockwell’s cloud-based solution for applications, will transform the way you work.

Video: Transform the Way You Work with FactoryTalk Hub

1. FACTORYTALK HUB CAN UNIFY YOUR APPLICATIONS

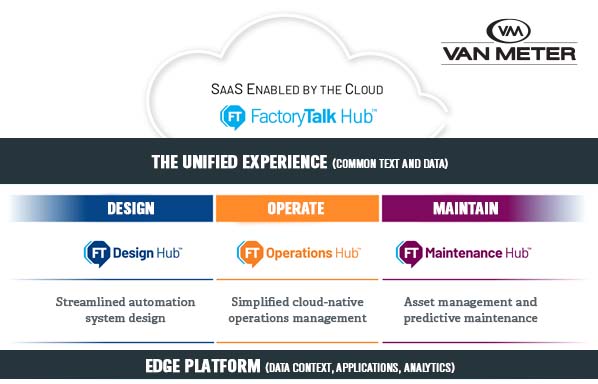

Whether you are designing applications, managing operations or scheduling maintenance, FactoryTalk Hub provides a unified experience for you and your team members. With all your applications hosted and supported within FactoryTalk Hub, you can more easily collaborate and do your job from anywhere in the world while also working with Edge-based applications at the point of production to deliver real-time performance for time-sensitive applications.

2. FACTORYTALK HUB HARNESSES THE POWER OF THE CLOUD

Operating in the cloud allows you to quickly scale the size of your operations without having to worry about the support cost, patching and resources it takes to host your own servers. The applications you are using in FactoryTalk Hub are designed by experts who know the factory floor, which gives you the ability to leverage the expertise of the cloud provider. It’s the best of both worlds.

3. FACTORYTALK HUB INCREASES DESIGN EFFICIENCY

Designing with FactoryTalk Hub helps users work more efficiently and effectively. Instead of having to load software on individual computers, you can connect to the cloud and start designing immediately. FactoryTalk Twin Studio, for example, is an application that will be released soon within the FactoryTalk Design Hub that provides your team with the design software they already use without having to install or support software yourself. As you try to build the optimal production line or factory of the future, being able to connect to the cloud and have software applications preloaded will allow you to do more in less time.

4. FACTORYTALK HUB IMPROVES QUALITY AND PRODUCTION

If you have your own Enterprise Resource Planning (ERP) system or Manufacturing Execution System (MES) and your challenge is quality, you can use the Plex quality management system (QMS) within FactoryTalk Hub alongside your existing MES or ERP system. Plex allows you to set quality parameters, monitor production and escalate your response to solve quality issues and get the quick return on investment that you need.

Because FactoryTalk Hub operates in the cloud, you do not have to invest in the infrastructure and a team of programmers to patch and support your MES. With an MES within FactoryTalk Hub, like Plex, you can leave that support to the Plex team in the cloud and focus on what is most important for your team—creating more value for your customer.

5. FACTORYTALK HUB IMPROVES MAINTENANCE EFFICIENCY

Using a Computerized Maintenance Management System within FactoryTalk Hub, like Fiix, allows you to reduce downtime by using historical data and analytics to generate schedules for more predictive maintenance. Scheduling maintenance based on regular time-based intervals does not account for running hours and is not the best use of your resources. Instead, monitoring key system parameters with Fiix to schedule maintenance based on condition is more efficient and will boost your production through more uptime and less maintenance.

NEXT STEPS

Keep your eyes on the exciting new applications that will be released within FactoryTalk Hub in the coming year. Please contact Van Meter and speak to one of our specialists if you would like to see how FactoryTalk Hub and working in the cloud can make you more productive and efficient.

ARTICLE BY:

KARL SCHMIDT

EMPLOYEE-OWNER, INFORMATION SOLUTIONS ARCHITECT - AUTOMATION & TECHNOLOGY