Everything You Need in Your Quality Management Toolbox

- March 6, 2025

- Best Practices

- Automation

How manufacturers can build a strong foundation and optimize quality processes

Just like a hammer with no nails or a pencil with no sharpener, there’s not a standalone quality management tool that will minimize waste, reduce scrap and optimize yield. Improving your manufacturing quality requires a complete toolset that helps you collect, record and use data to optimize quality processes. Not sure where to start? Don‘t get overwhelmed with your quality options. Use these tools to build your foundation then optimize quality performance.

BUILD YOUR QUALITY FOUNDATION

It seems like everything has an artificial intelligence (AI) solution built into it now. Surely you should use AI tools to improve quality too, right? Yes! AI in manufacturing is here to stay, but before you start researching methods of optimizing your quality performance with AI, make sure you’ve implemented these components of a strong foundation:

Reliable & Secure Network Infrastructure

When you use smart devices and software solutions, everything is connected to your network, so your first step is building a digital ready network infrastructure. Rather than a hodge podge of Ethernet, Profibus and DeviceNet connections, your network should be connected on a common protocol built around NIST (National Institute of Standards and Technology) cybersecurity standards.

Start by performing an installed base evaluation, which is an audit that catalogs where your equipment is located, which parts may be obsolete and where you may be vulnerable to downtime risks. Once you have performed this baseline evaluation, you can prioritize network infrastructure investments that provide the greatest ROI now while helping you scale towards your goals for the future. When you decide to add smart devices, software and AI solutions to optimize your quality performance, you will have a firm foundation in place.

Smart Devices and Sensors

Before you can start using your data to improve quality management, you need the right devices in place to monitor performance and collect data. Instead of relying on someone to visually inspect each stage of the production process and manually record quality data, using smart devices like drives, PLCs, sensors, machine vision and scanning can automate quality checks and eliminate those error-prone, time-consuming manual processes.

Fixed industrial scanning and machine vision solutions can visually inspect products and processes to verify they’re correct, while smart sensors can monitor environmental conditions like temperature, pressure and vibration. Using a combination of machine vision and smart sensors gives you a snapshot into the environmental conditions when a quality incident occurred, so you can identify what caused the issue, remediate the problem and futureproof the process.

Digital Quality Management System (Plex QMS)

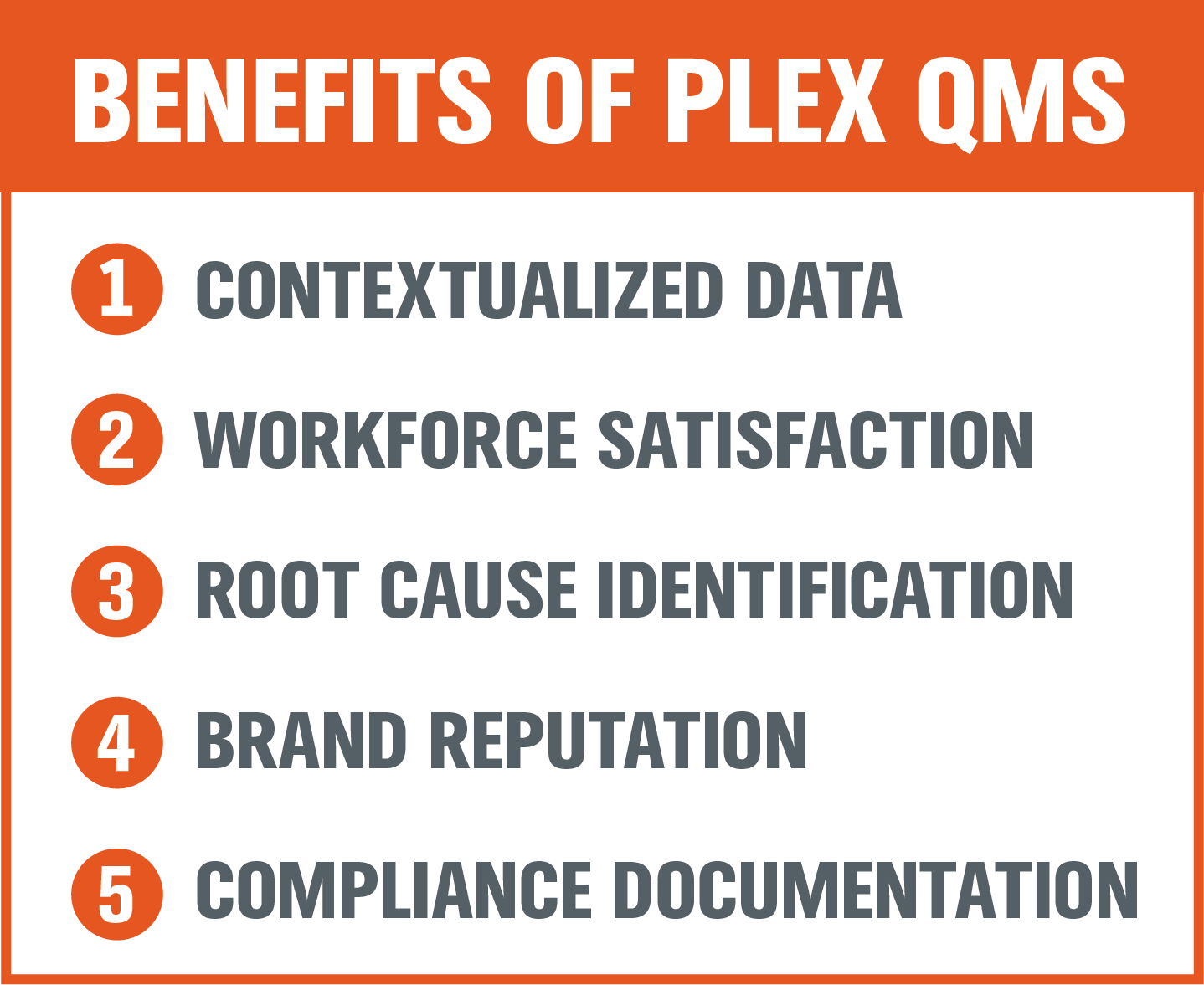

Once you have smart devices that can collect large amounts of data, how do you turn that data into actionable insights? Using a digital quality management system (QMS), like Plex QMS, automates data reporting, check sheets and documentation, so you have access to more consistent, reliable data that helps you make faster, smarter decisions.

Without a digital QMS, finding the root cause of a quality incident can be like finding a needle in a haystack (if you ever find it). Using a digital QMS enables you to pinpoint the process step where a quality incident took place, so you can root cause analyze the issue more efficiently. Then, a digital QMS enables you to make changes to quality documentation in one place and have changes cascade to all relevant settings within your control plans and check-sheets, so you can prevent the same issue from happening again.

You can also use data from your digital QMS to automate compliance documentation and prove your compliance to quality requirements. Instead of taking weeks to manually gather documentation on your production quality in preparation for an audit, you can access the same report in the digital QMS in minutes.

HELP BUILD MY QUALITY FOUNDATION

Do you have a strong foundation for quality management? Where can you optimize quality processes? Wherever you are on your quality management journey, trust Van Meter’s smart manufacturing experts to help.

Get StartedOPTIMIZE YOUR QUALITY PERFORMANCE

Once you have your foundation of reliable network infrastructure, smart devices and a digital QMS, you can start exploring how using AI can optimize results. These are some of the tools to help you optimize quality performance.:

FactoryTalk Analytics VisionAI

Any vision inspection tool can inspect products to perform quality checks, but Rockwell Automation’s FactoryTalk VisionAI gives those tools the power to learn as they go and adapt to make better decisions on whether products pass or fail quality checks. Instead of a black and white pass-or-fail system, VisionAI can make smarter decisions to detect the subtlest anomalies. Over time, it will create new models on its own without having to be trained on every single product you plan on running.

FactoryTalk Analytics Pavilion8 Model Predictive Control

While your recipes probably don’t change very often, environmental conditions and other factors that affect the quality of your end product change all the time. How do you maintain consistent quality despite changing environmental conditions? With FactoryTalk Analytics Pavilion8 model predictive control, you can optimize processes based on long-term historical data regarding product quality in various conditions. The AI model learns which conditions affect the outcome of your product over time and adjusts parameters to achieve a more ideal outcome no matter the condition.

For example, if the ideal consistency of a product depends on its water content, the humidity in the air can cause the consistency to vary. A tool like Pavilion8 could assess the humidity in the air, use long-term data to see how the humidity has affected product consistency in the past and then change recipe parameters to add or subtract water to achieve the ideal consistency each time.

FactoryTalk Analytics LogixAI

When you don’t have a data scientist on hand to predict the behavior of your automation system, Logix AI works as a “soft sensor” to turn controller data into real-time predictions on product quality. Once you tell LogixAI what you want to predict and which parameters you want it to analyze, LogixAI will observe your production data and start to understand which data points are relevant to your output.

Once it has observed enough data to make reliable predictions, it will create models and test them until it comes up with the best solution to achieve your ideal outcome. You can then integrate the prediction into your control processes to achieve more consistent quality outcomes.

FactoryTalk Batch

As with manual data collection and reporting, introducing manual processes to recipe management processes presents the risk of human error for food in industries like food and beverage and pharmaceuticals. Instead of relying on someone to manually adjust recipe information, FactoryTalk Batch automates recipe management and optimizes sequence of operations. FactoryTalk Batch can factor in all the products you plan to run for a day and give you the most efficient order in which you should run processes to optimize your workflows.

You also get access to historical data, so you can see recipe set points and how they affected product quality. You can then use that information to adjust your recipe in the future and achieve more optimal results.

COMPLETE YOUR QUALITY MANAGEMENT TOOLBOX

Do you have a strong foundation for quality management? Where can you optimize quality processes? Wherever you are on your quality management journey, trust Van Meter’s smart manufacturing experts to help. Let us know what quality challenges you face and which quality management solutions you’re most interested in.

Solve My Quality Challenges

Fill out the form below and a member of our team will get in touch soon.

ARTICLE BY:

JACKIE LAFLEUR

EMPLOYEE-OWNER, CUSTOMER SEGMENT MANAGER