Why You Should Use Coordinated Circuit Protection Devices

- May 26, 2022

- Best Practices

- Automation

You would not plug an Android charger into an iPhone, you cannot play Xbox games on a PlayStation and you should not combine all the flavors at the soda fountain in one cup (okay, that one is actually pretty good). Our electronic devices, our fashion and even our food and drink choices rely on coordination—just like circuit protection devices in a panel. Here is what coordinated rating means for circuit protection, why it is important and how you can make sure your panel is protected.

What is Coordinated Rating?

Short Circuit Current Rating (SCCR) is the short circuit current an industrial panel, component or group of components can withstand without causing a shock or fire hazard. Coordinated Rating means that an industrial component (e.g. contactor, motor, drive, etc.) and a circuit protective device have been tested together by Underwriters’ Laboratories (UL) and proven to meet a certain SCCR.

Manufacturers like Rockwell Automation typically have their circuit protective devices tested with their own industrial components to receive a certain SCCR. If your Rockwell contactor has a 5kA rating and is being used with a Rockwell circuit breaker with a 65kA rating, they might have a 65kA SSCR in the panel together. However, if you swap that circuit breaker with a non-Rockwell breaker, they will not have the same SCCR. Since they have not been tested together by UL, the SCCR would drop to the lowest possible rating between the two devices—in this example, 5kA.

Why is Coordinated Rating Important?

If you have mixed and matched circuit breakers and devices from different manufacturers in your panel and a UL inspector arrives to investigate, you are probably on track to bomb the test—both figuratively and literally. First of all, safety is the top priority. If you get a short in the system and your panel does not have a sufficient SCCR, you are at risk of the circuit protection device exploding, starting a fire, injuring people and damaging equipment.

In addition to risking plant safety, you also will fail a safety inspection. If your customer needs 65kA protection and there is an uncoordinated breaker in the panel, the SCCR will not be 65kA, and it will fail the UL inspection. An off-brand breaker may provide enough protection, but it is risky. If it does not work, and someone is injured, you (and your company) would be held liable.

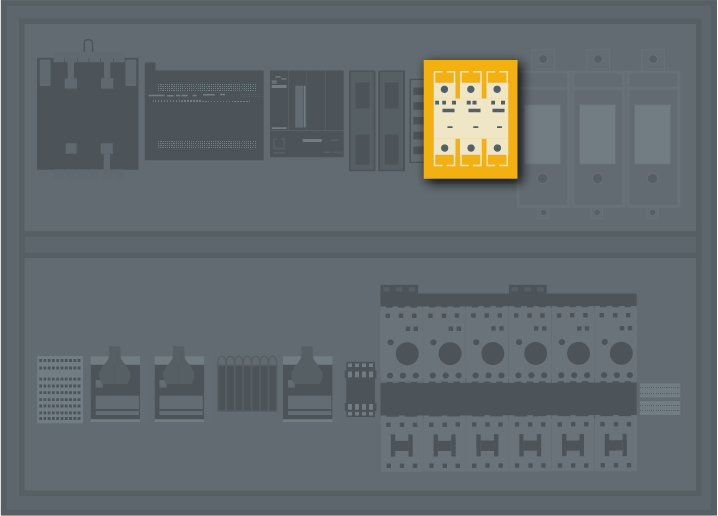

Control Panel, Circuit Breaker

How Do I Stay Coordinated?

The simple answer is to make sure all devices in your panel are made by the same manufacturer. If that is the case, you can be confident that all are UL tested together and coordinated. If you know the devices in your panel that need circuit protection, Rockwell’s Global SCCR Tool makes it easy to make sure your panel has an adequate SCCR. This tool shows the breaker (or fuse) and wire you need based on the devices you are using.

Once the selection tool determines the circuit protection devices you need, you can print out a sheet that displays that information. If a UL inspector comes into your plant, you can show them that sheet and demonstrate that your panel is coordinated. If you are unable to determine what you need with the tool, contact Van Meter, and we can help make sure your panel is coordinated with the sufficient SCCR.

The days of bargain hunting for the lowest price on circuit protection devices and patchworking a panel together are over. In the past, coordination was a preference. Now it is a necessity—not only to pass an inspection, but it could save a life.

ARTICLE BY:

MATT HENNING

EMPLOYEE-OWNER, TECHNICAL SPECIALIST - SMART DEVICES