How to convince your boss you need on-machine motion control in 6 easy steps

- May 8, 2024

- Best Practices

- Automation

Comparing Centralized and De-centralized Rockwell Automation Motion Control Systems

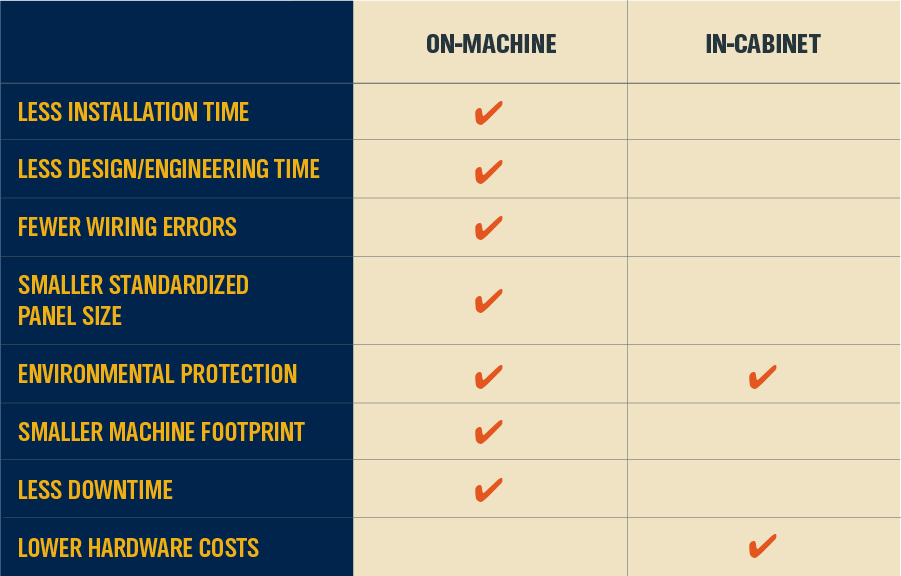

Did you know decentralizing your servo drives and technology can help you meet changing customer demands, reduce production time, save space on your plant floor and more? While the hardware can be more expensive than a traditional in-cabinet solution, the total system savings, simplicity and flexibility quickly make up for it. Need help convincing your boss to consider an on-machine system? Persuade them by following these steps.

STEP 1: LEARN THE DIFFERENCE BETWEEN ON-MACHINE (DE-CENTRALIZED) VS. IN-CABINET (CENTRALIZED) MOTION CONTROL

What do we mean by on-machine vs. in-cabinet? On-machine motion control refers to integrating the servo drive directly onto the machinery, which allows for simple setup and quicker access. In-cabinet motion control houses components within a separate, centralized enclosure or cabinet, which can offer additional environmental protection but takes up valuable floor space and complicates design, installation and maintenance.

STEP 2: EXPLAIN HOW MACHINE FLEXIBILITY AND SCALABILITY WILL HELP YOU ADAPT TO CHANGING DEMANDS

Housing the drives, PLC and other components in one panel can be fine if your machine never changes, but if your machine doesn’t change, will you be able to meet the ever-changing demands of your customers? Adding functionality to the machine typically means adding components to your panel. Will there be enough room? Can the components still function without overheating the panel?

If they will no longer fit in the existing panel, you have to purchase a larger panel then reconfigure the layout, determine if the internal temperature will be okay, take up additional space on your plant floor and rewire the new panel. With a decentralized, on-machine solution, your cabinet size will never change when you upgrade your machine. The only components in the cabinet are the power supplies and PLC because the drives are integrated on the machine.

STEP 3: CALCULATE THE INSTALLATION AND DESIGN TIME, LABOR AND MATERIAL COSTS

With an on-machine distributed servo drive, like Rockwell Automation’s ArmorKinetix® drives, devices on the machine get wired back to the drive instead of all the way back to the panel. When you wire everything to the on-machine drive instead of back to the panel, you can spend less money on wire and the labor it takes to wire your panel. In fact, an on-machine design can reduce cabling by up to 90% and lower overall system costs by an average of 30%.

“An on-machine design can reduce cabling by up to 90% and lower overall system costs by an average of 30%”

It also takes less time to design panels for the machine, as you can build more modular, standardized panels. Even as the functionality of your machine grows, your cabinet size stays the same. That means you can pre-build and pre-wire machines and put them together on your floor. When you get an order, you can wire it up with quick disconnects and send it out the door. It saves engineering time and reduces commissioning so you’re able to get it to the customer quicker.

STEP 4: GIVE THEM PEACE OF MIND WITH FEWER RISKS

Less wiring and fewer terminations means there are fewer opportunities for human error or damaged wire. If things get mis-wired, it is time consuming to figure out where the error occurred. With an in-cabinet solution, you would have to trace the problem back to the panel instead of checking from the device back to the on-machine drive.

An on-machine solution also reduces your downtime risks because it’s quicker and easier to swap out the drive or drive motor if something goes wrong. You can simply swap out the drive on the machine with quick disconnects instead of getting into the panel, unwiring components and re-wiring them again. If your boss asks you how on-machine drives withstand the plant floor environment outside of the cabinet, you can tell them they are IP67 rated to withstand washdown and harsh environments. No risk there.

STEP 5: SHOW THEM WHAT YOU CAN DO WITH ALL THE EXTRA PLANT FLOOR SPACE

Plant floor space is expensive. Do you have a bunch of spare space to add new machines? Probably not. When you don’t have to upgrade the size of your enclosures, you can save more space on the plant floor. With an in-cabinet solution, enclosures can get really large and heavy, so you can’t put them on top or inside of the machine. Instead, the enclosures typically take up space next to the machine or somewhere against the wall nearby.

With an on-machine solution, your enclosure is small enough that you can bury it within the machine instead of having a freestanding enclosure. With a smaller machine footprint, you can either add more machines (and more production!) to your plant floor or produce more with less space.

STEP 6: JUSTIFY THE HARDWARE COST

If there is a drawback to an on-machine solution, it’s the up-front cost of the ArmorKinetix drives. But while an on-machine motion control system is more costly up front, you can justify it with the total soft cost savings above like simpler design, scalability, faster installation, reduced maintenance time and fewer wiring errors.

The amount of cost savings depends on the number of axes of movement on the machine. Axes of movement are the directions along which components can move, and more complex machines require additional rotational axes and multi-directional movement. Adding axes requires additional drives and motion control components and makes an in-cabinet solution much more elaborate and complicated.

If you only have three or four axes of motion, there’s not a lot of wiring required, your cabinet won’t change much in size and an on-machine solution like ArmorKinetix might not be worth the added cost. But when you have 20 or 30 axes of motion and the potential to grow, the savings quickly add up.

THE FINAL VERDICT:

If you have a large machine with many axes of movement to control, the soft cost savings of an on-machine solution outweigh the upfront costs.

LEARN MORE ABOUT ARMORKINETIX AND ON-MACHINE MOTION CONTROL

Would an on-machine motion control system like ArmorKinetix help you save time and money? If you want to discuss an application or ask questions, reach out to your Van Meter account manager, or call 1-800-247-1410 to discuss with one of our smart machines specialists.

ARTICLE BY:

GEORGE ROVOLIS

EMPLOYEE-OWNER, SMART MACHINES & ROBOTICS MANAGER